Aboveunity.com - Lighting Up the Darkness

Donate

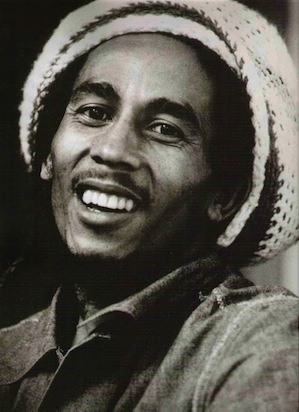

Two days after being shot, just before appearing on stage, Bob Marley said:

The people that are trying to make the world worse, never take a day off, why should I. Light up the darkness!

Aboveunity.com - Where REAL Free-Energy Machines Exist!

Above Unity = COP > 1.0 = Free Energy Machines

Aboveunity.com is the home of Truth! We have Free Energy Machines running, and we were the very first to share them with you all!!! No where else in the world will you find detailed, accurate information, on how to Build a Free Energy machine! We have many independent Replications showing you how easy this is! ONLY Here! The Home of Energy Machines!

There is NO Magic, there is only Understanding!

The Energy Machine Race is already WON, I am the Winner! The other idiots are all misleading you with Lies and Deception!

We have completed some of Sciences Incomplete areas! With this completion, we can use them to our advantage, one area, Faraday's Law, now has an Asymmetrical Electromagnetic Induction, which means, we can have an Open Machine, "Generate" Electric Power, that does not have any Negative Effects on the Input Power!

Yes, you heard correctly! We have tested and working theory and Machines, proving, what we are sharing works, and can NOT be disputed! Only Idiots dispute Facts!

Name and Shame the Trolls

Banned and Disgraced Ex-Member, fighter, aka Aurelian Iordache, Professional Plagiarist, you are NOT welcome!

You can read a little about what this person has done to deserve this Naming and Shaming Here

Banned and Disgraced Ex-Member CD_Sharp, also in the same boat as fighter, he is not welcome back ever! Another plagiarist, helping his buddy steal all my work, ideas and website designs and more! These people are satan worshippers! Evil scum! Lying is like breathing for these loosers! Each breath they take is a waste of the free air God gave Adams Children! These people are mentally dreranged Lunies! All of them! They all have the average IQ of a Bucket of MUD! Thats going easy on them! And that's a Combined Average! These two Monkey's are just very low IQ Idiots! Many more exist!

None of you Banned and Disgraced Trolls are Welcome! I will just keep banning you Loosers! These people are so far from the truth, so far from working machines that are practical, that they may as well be playing in the sand pit with tonker trucks!!!

I would say Banned and disgraced Ex-Member, fighter, is one of the worst for destructive behaviour, and the easiest to catch doing so many Idiot Things! Oh the dumb things this moron has done!

They have Nothing of value, nothing valuable, nothing to share except the same O'l Propaganda Non-Sense that the other forums have shared for the last 40 Years! "Final Secret of Back EMF explained", Really, what a bunch of Pork Chops! Disgraceful!

Idiots begets Idiots!!! Its so embarrasing, having so many Dumb Ass, Brainless Freaks, in our Species!

There are many more trolls! Many more! Some on other Forums, all having ZERO Progress in the many Decades of intense Study and Research! It is Statistically Impossible to continuiously have ZERO Progress! Just a bunch of Monkey's taking orders from a Fake, Plagiaristic, Lying, god!

These Evil People have held you all back for Decades! With their LIES, and Deception!

We have changed the World!

Fact: I have shared with you all, the Answer to Energy Machines, we have Machines running above the Unity Boundary, and no "Law's" of Science have been Broken! Too many Lunatics have misled you for far too long!

Click the + and see for yourself:

We are Light Years Ahead!!!

Proof, and the Dumb Dumb Club cant see the Forest for the Trees! When too many Dumb Stupid Idiots flood the Forums, claiming to be Guru's, and the truth is, they have no idea what so ever, they make a mockery of the Truth! Right here, it's been here for nearly a Decade, you can SEE The Truth:

Start Here → Builders Guide to Aboveunity Machines

Start Here → Builders Guide to Aboveunity Machines

There are two mistakes along the way to Mastery: Not Starting and and not going all the way!

Cite: Master Shi Heng Yi

On rare occasions, Sweet saw this effect, called self-oscillation, occur in electric transformers

Ref: http://merlib.org/node/5282

The Answers you seek are right here:

I have provided an entire Thread: Chris's Non-Inductive Coil Experiment and 11 videos on this showing you how to approach this Technology! I have given you all of the data to make this work, and more, to make this, not just a TOY, to make this Power very much more than just a few Globes!

My Friends, when I see 10 successful replications, I will release another Video showing a bit more work, again we have had quite a few successful replications already!

Independent Replication is Scientific Proof:

Do the Math in these videos! COP > 1.6 in both Machines!

Technically, My Friend Wistiti was the first, but for undisputable numbers, we have to see Tinmans effort.

Tinman was the first: COP = 1.7

Others followed, like Captainloz: COP = 1.9

Hey Chris,

If people watch your videos its all in there. My experiment is proof of that. I was feeling very frustrated for a long time but then I stumbled on to your youtube channel and it inspired me to keep going. I actually have your book from way back, I wish now just stayed with it but I went down the Ruslan and Akula rabbit holes for too long without understand Asymmetry and the re-gauging process. Anyway mate I'm just trying to say you should be proud of yourself. You are doing a great thing here!

Cheers,

Loz

Ref: Captainloz COP = 2.0

COP = ∞

We have Self-Running Machines, Our Flashlight that a Member of AboveUnity.com has achieved:

Others also, some may not want their names used? Security for people is important to me, but eventually, we must do this as a Team and make a Stand!

Others have also achieved Above Unity, Marcel has also shared with you all, freely:

Aboveunity.com is Light Years Ahead of the other Forums!

Lighting up the Darkness!!!

Its time to make things Right, get Right by yourself, trust what's in your Heart! Never pay a Power Bill ever again! Apply this knowledge and set yourself Free!

Start Here → Builders Guide to Aboveunity Machines

Start Here → Builders Guide to Aboveunity Machines

Category: Hardware

Measurement Block PCB

Category: Devices

Classic's Experiments

Category: News

Be Prepared - The Grid Is Going Down

Category: Resources

Coil Geometry

Category: Resources

5KW Generator Teardown

Category: Meet and Greet

Hello everyone.

Category: Replications

Antares & Markus POC Replication

Category: Replications

Falcons COP Experiments

Category: Devices

Rakarskiy's COP=1.4

Category: News

Current Affairs — Future Hopes

No one online at the moment

In physics, scalars are physical quantities that are unaffected by changes to a vector space basis. Scalars are often accompanied by units of measurement, as in "10 cm". Examples of scalar quantities are mass, distance, charge, volume, time, speed, and the magnitude of physical vectors in general.

You need to forget the Non-Sense that some spout with out knowing the actual Definition of the word Scalar! Some people talk absolute Bull Sh*t!

The pressure P in the formula P = pgh, pgh is a scalar that tells you the amount of this squashing force per unit area in a fluid.

A Scalar, having both direction and magnitude, can be anything! The Magnetic Field, a Charge moving, yet some Numb Nuts think it means Magic Science!

Hello my children. This is Yahweh, the one true Lord. You have found creation's secret. Now share it peacefully with the world.

Ref: Message from God written inside the Human Genome

God be in my head, and in my thinking.

God be in my eyes, and in my looking.

God be in my mouth, and in my speaking.

Oh, God be in my heart, and in my understanding.

More than anything else, your contributions to this forum are most important! We are trying to actively get all visitors involved, but we do only have a few main contributors, which are very much appreciated! If you would like to see more pages with more detailed experiments and answers, perhaps a contribution of another type maybe possible:

They REFUSE to tell me why!

The content I am sharing is not only unique, but is changing the world as we know it! Please Support Us!

Thank You So Much!

-

Chris

350

Chris

350

-

---open-tesla-research.jpg?width=20&crop=0,0,20,20) akoteles

100

akoteles

100

-

Arya 100

-

Gucio_81

92

Gucio_81

92

-

FringeIdeas

90

FringeIdeas

90

-

thaelin 50

-

skywatcher 20

-

anarsu 20

Ere many generations pass, our machinery will be driven by a power obtainable at any point of the universe. This idea is not novel. Men have been led to it long ago by instinct or reason. It has been expressed in many ways, and in many places, in the history of old and new. We find it in the delightful myth of Antheus, who drives power from the earth; we find it among the subtle speculations of one of your splendid mathematicians, and in many hints and statements of thinkers of the present time. Throughout space there is energy. Is this energy static or kinetic? If static, our hopes are in vain; if kinetic - and this we know it is for certain - then it is a mere question of time when men will succeed in attaching their machinery to the very wheelwork of nature.

Experiments With Alternate Currents Of High Potential And High Frequency (February 1892).

---open-tesla-research.jpg?width=50&crop=0,0,50,50)

---open-tesla-research.jpg?width=15&crop=0,0,15,15)