My Friends,

An Experiment today, I hope it works out!

Coil Formers or Coil Bobbins are one of the hardest things to come by! In the past I have made them from CNC Cut Plexi Glass, or Acrylic Plastic:

Ref: CNC Machine

This process is expensive and wasteful!

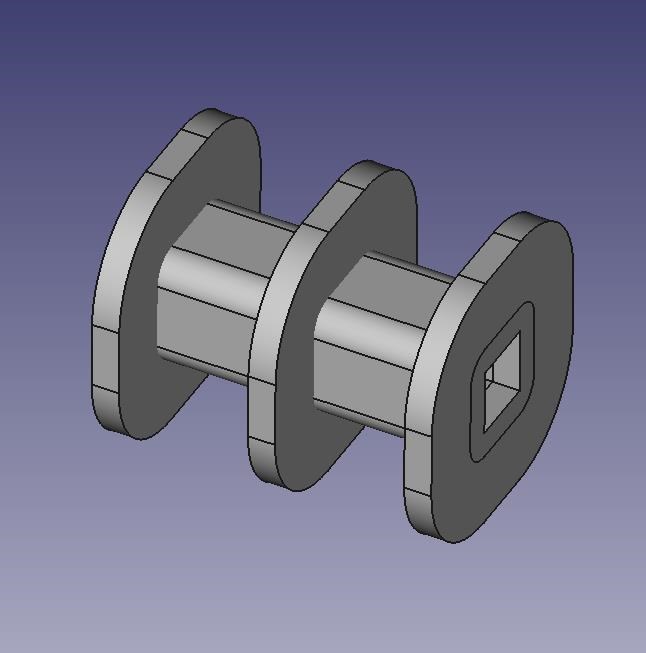

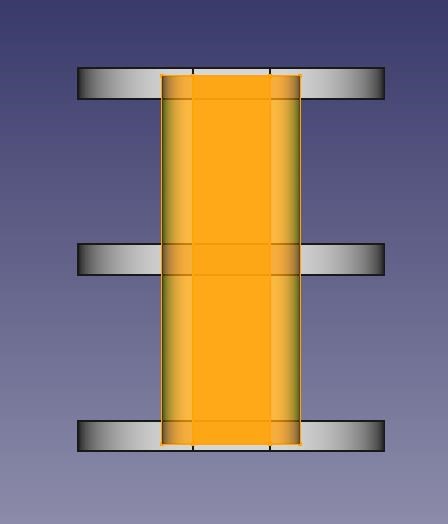

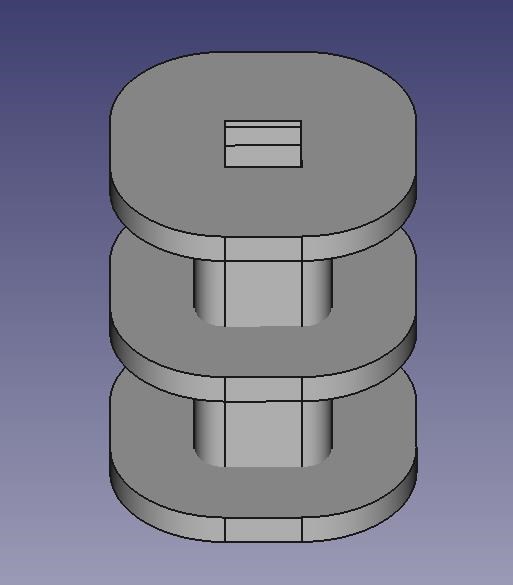

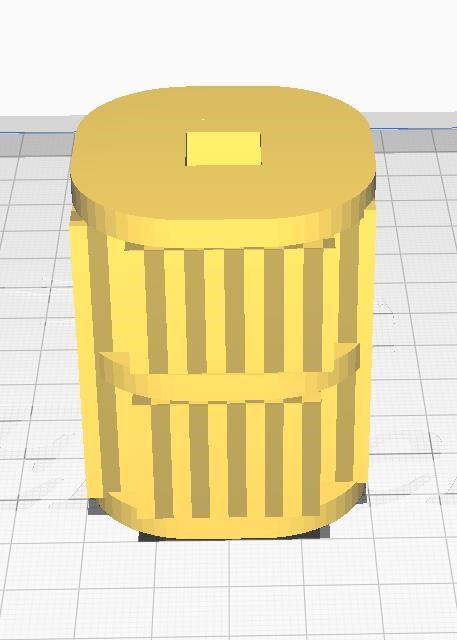

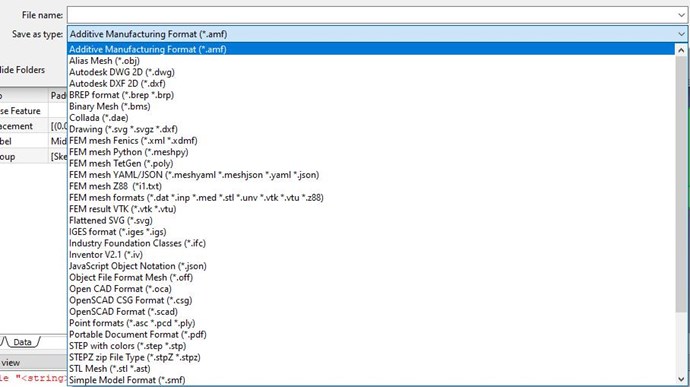

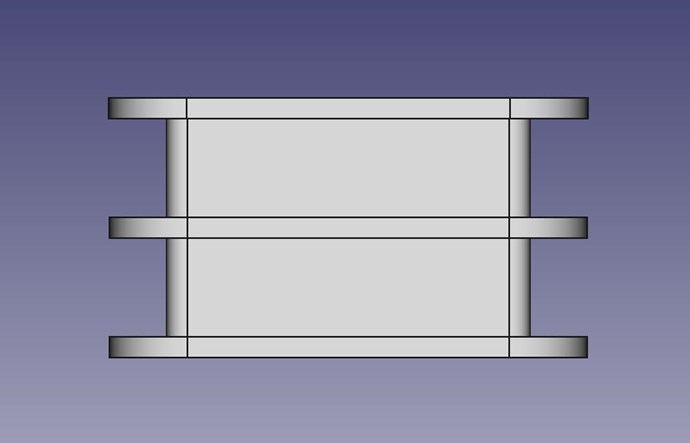

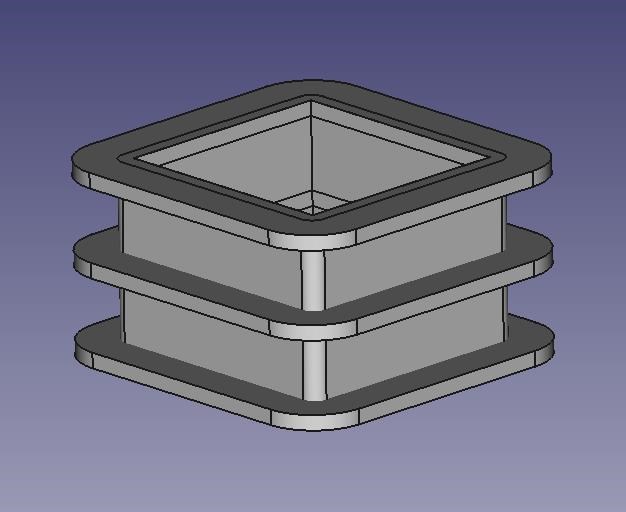

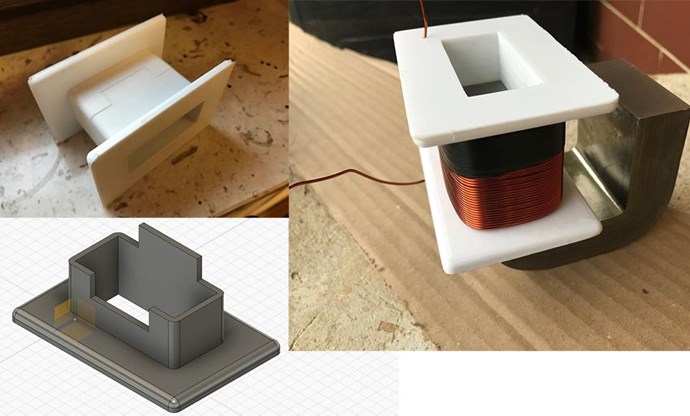

I have designed a Coil Former/Bobbin in FreeCAD and have basic dimensions set:

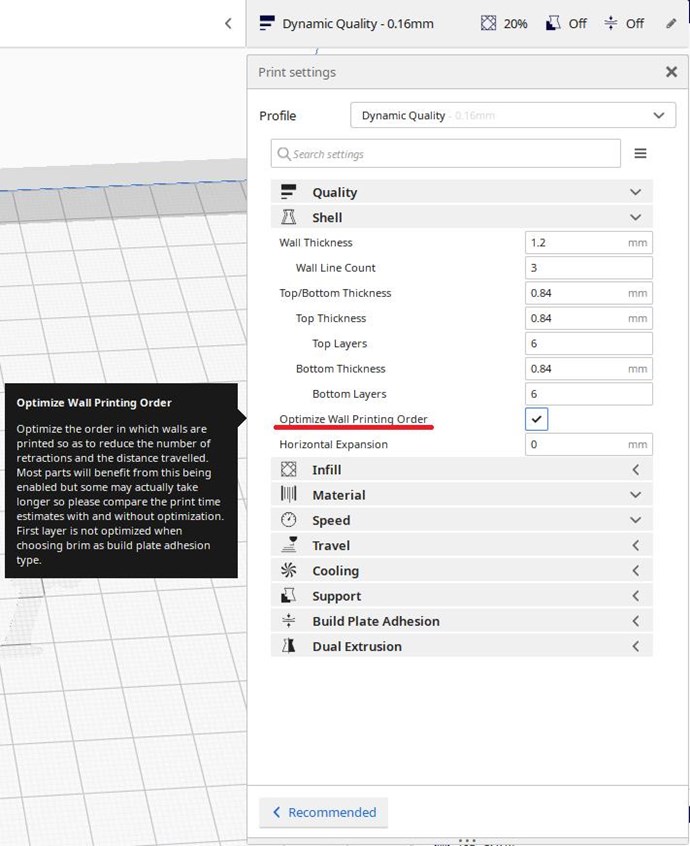

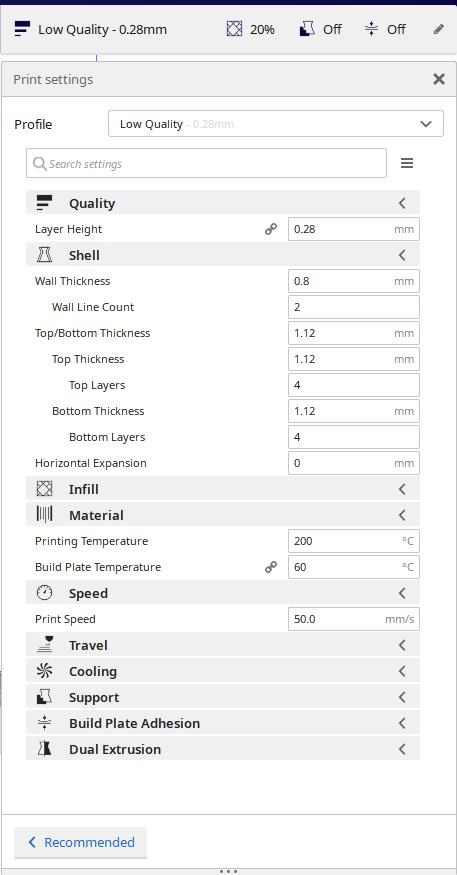

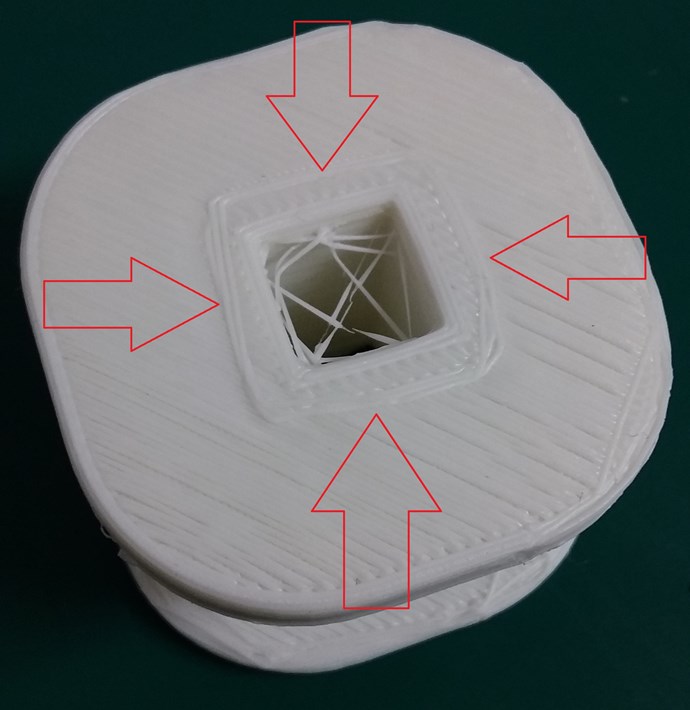

I am new at this, so I believe I may need Supports to help this turn out ok. With all experiments, the process will be perfected over time.

What I use:

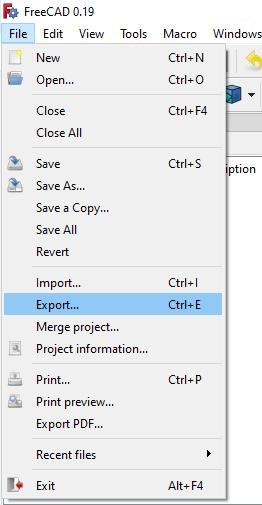

- FreeCAD - Free CAD Design Software with hundreds of Videos on YouTube.

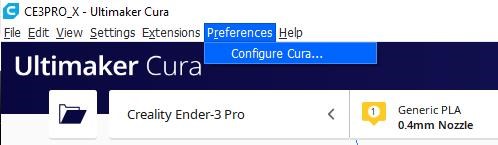

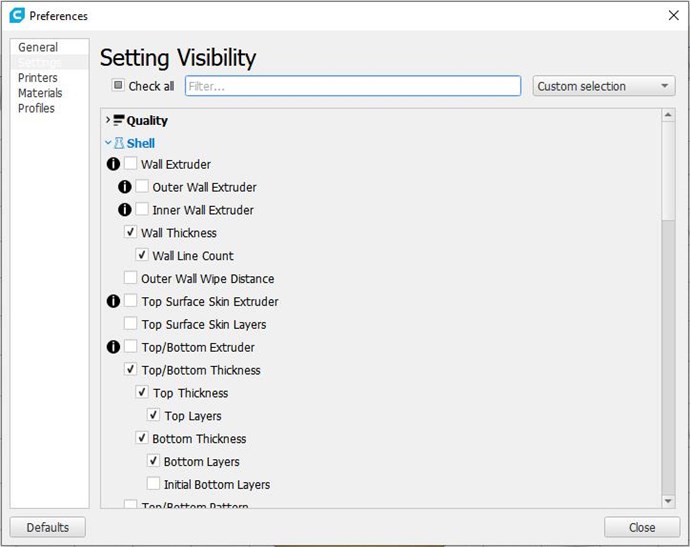

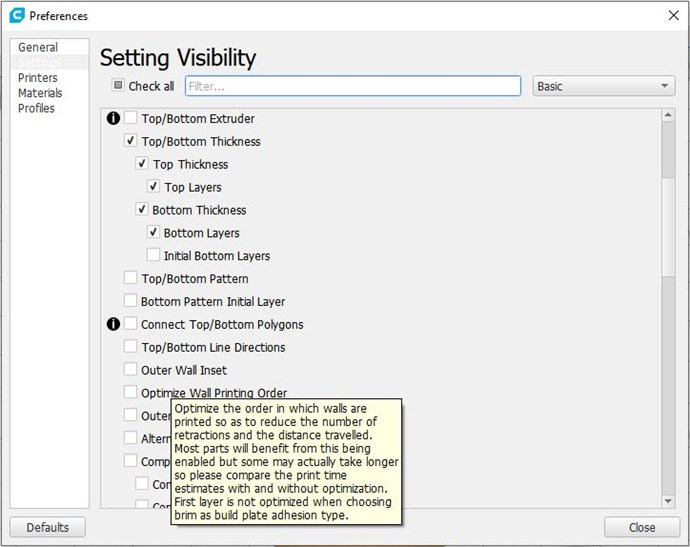

- Ultimaker Cura - Free also excellent for 3D Printing, does all the Splicing and so on.

- Ender 3 Pro an excellent and very cheap 3D Printer, I paid $260 for mine.

Very easy to put together!

Supports seem fairly easy, here is a good video:

I will update you asap with the result!

Best wishes,

Chris

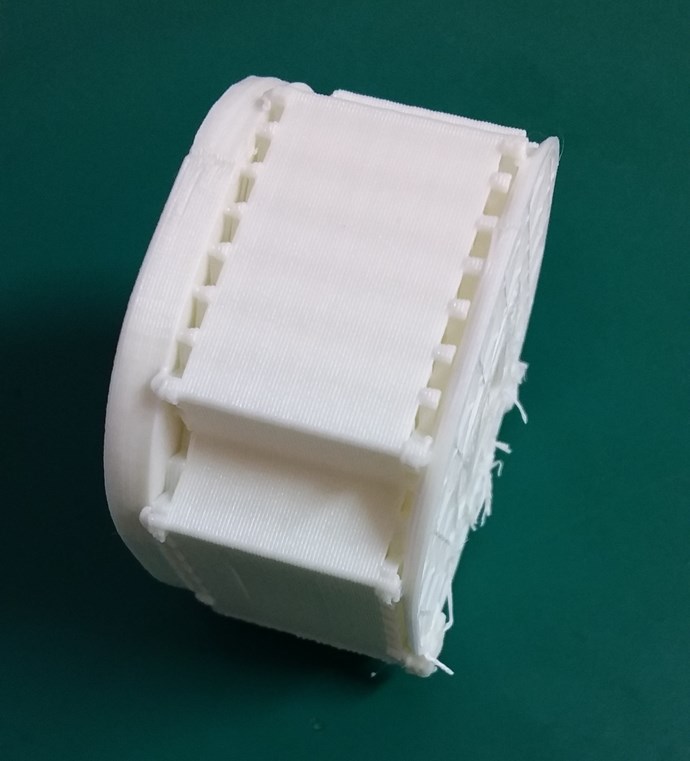

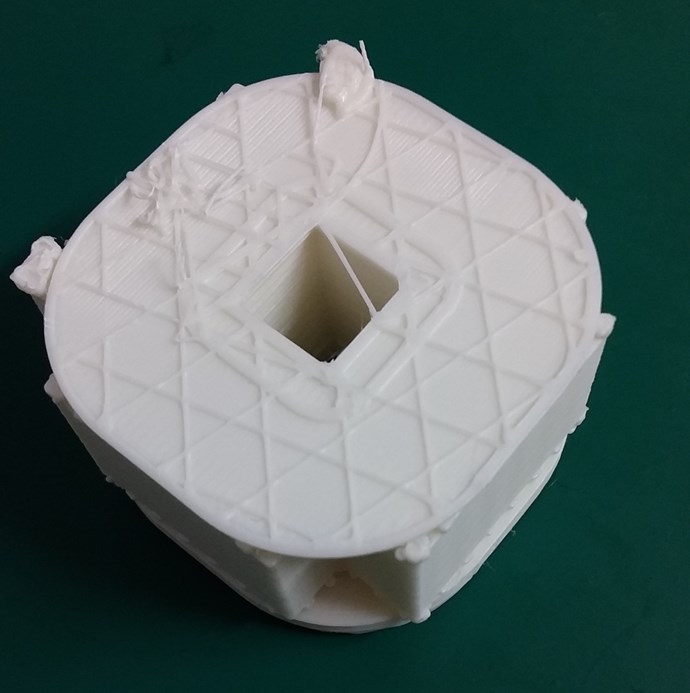

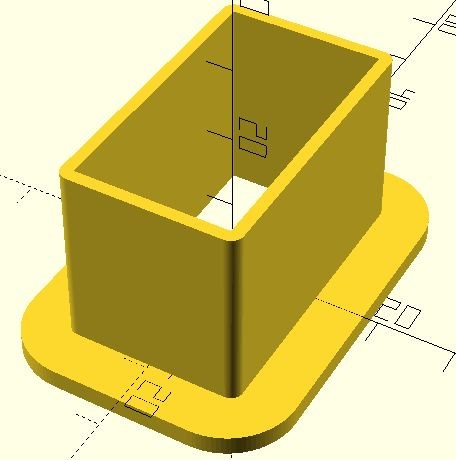

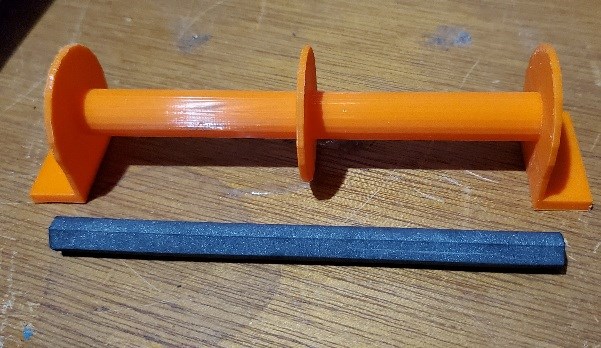

One other former for a ferrite rod.

One other former for a ferrite rod.

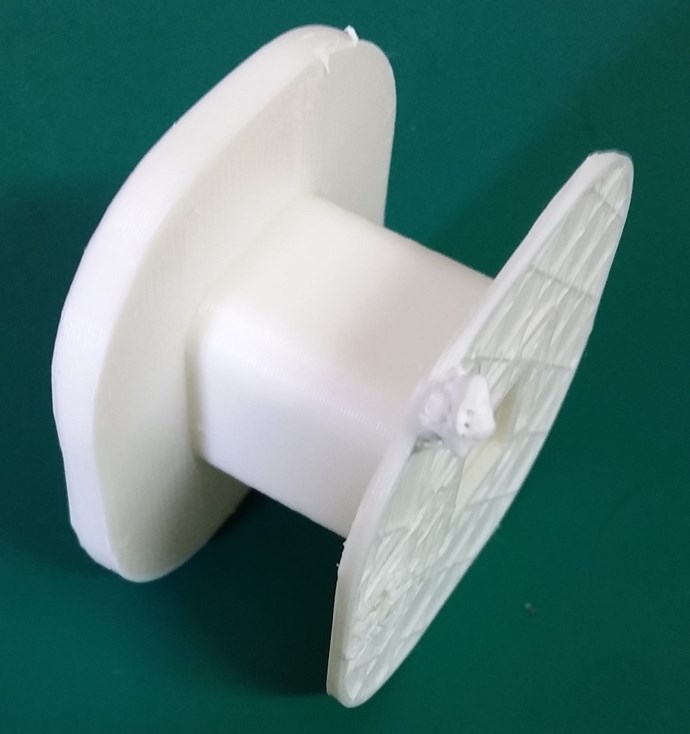

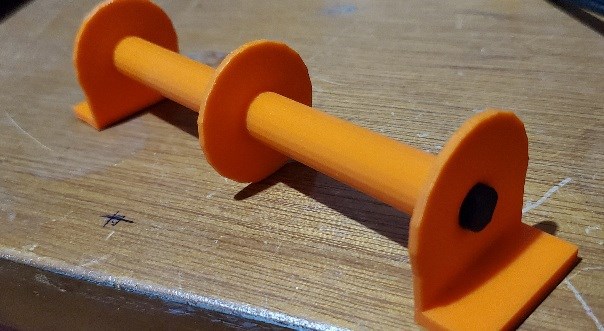

Hi builders! Yesterday I have created my first coil former using thinkercad (free and really easy). Slicing it with Cura and printing it with my Creality Ender3. Really 3D printer are a part of our future!

Hi builders! Yesterday I have created my first coil former using thinkercad (free and really easy). Slicing it with Cura and printing it with my Creality Ender3. Really 3D printer are a part of our future!

.jpg?width=690&upscale=false)