Cornboy

posted this

17 February 2019

OK MM, have done some reading and it looks like i need about 400v 200uf cap across bridge output.

Also i happen to have a 3kva 1 to 1 isolation tranny on hand. The caps i will have to look through all my unpacked old Don Smith stuff, sure to have what i need there.

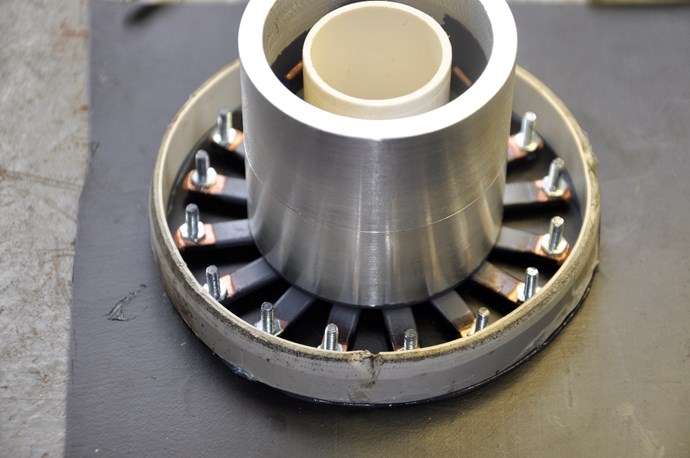

The commutator is another story, the outside housing, being a pvc plumbing fitting, is too flexible, and prone to distortion

Will make new smaller one with thick aluminum housing and comm bars embedded in resin, then machine the brush surface.

I have some Garlic payments coming in shortly and am considering having parallel builds going, what i have now and a C core build.

Also on doing some research, i have found a company that makes toroidal shape Amorphous cores that can be custom built, even into a thin walled tube, which i am thinking, back in Clemente's day, if he used a cylinder Gr it would most likely have been soft iron sewer pipe or similar.

Thanks again for the help, Cornboy.

![]()